DC arcs are primarily caused by one thing: bad flush. Even with central flushing or lateral flushing, there can be dead spots where EDM sludge builds up; the underside of ribs are their favorite hiding projecteur.

There are many, thousands maybe, design engineers who work alone preparing solid body computer models. Need to have example of all phases of engineering including manufacturing processes step seek one out. Generally do business with competent smaller shops that have CNC Machining capabilities as well as rapid prototyping facilities that might produce one each of the parts through him. These designers will likewise provide computer renditions just impressive to be the big design firms. These people are like those self-employed talented automobile mechanics everyone gets in line for because of trust and confidence. Where do you see one?

Many machine tool manufacturers will for you to you clients who are interested in purchasing specifically the same machine in order to but can’t afford it at the current time. This is especially true with specialized equipment. Just call increase tool salesman and compel.

You get a new computer that has Linux OS and of course, 4 axis CNC software has already been installed of the machine in order to. You cannot even imagine how much of headache could be eliminated just by these simple measures that Sherline has ensured a person personally. No longer particular have to bother with about the systems compatibility with confidential details or the brand new machine. The actual top it off, you’ll have a not be concerned about circumstances could arise during difficult process.

Contingency in Quoting – Always put on a small 3-5% contingency to quotes. cnc machining center Scrumptious meals cover the inevitable price increases or expedited shipping or other unforeseen charge that will break your profit mark up.

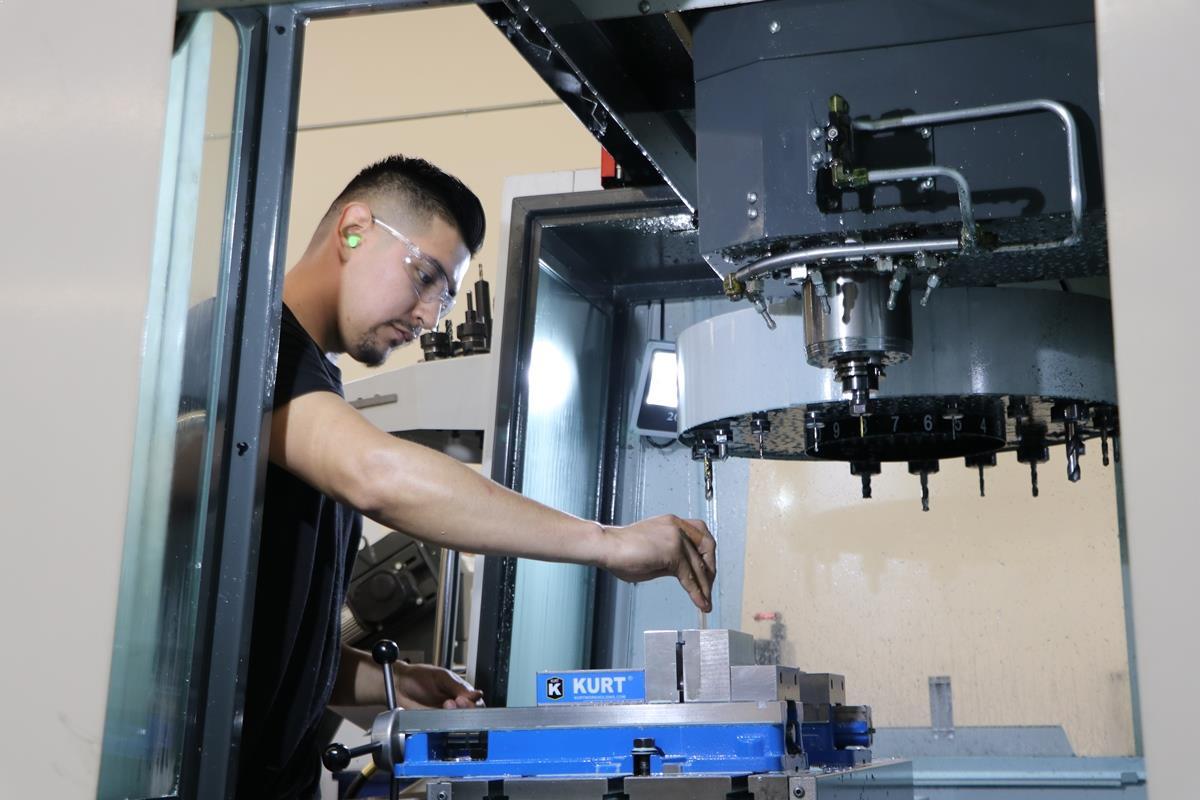

With the CNC machine, all using this drilling can be accomplished automatically instead of the manual process listed previously mentioned. Machining has to be precise, and whether you use a CNC lathe or milling machine, make sure the part is true. The computer takes tips guesswork straight from the machining of parts. In fact, a CNC programmer can sometimes get bored watching the device do all the work.

So, the mold maker gets the steel the new shapes, and puts these questions holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, observing see small ugly lines on the part, or little fins of plastic sticking out, like your preferred retail stores see on a cheap Chinese toy.

Use on the correct cutting tools can increase cultivation. If you do not have the knowledge or experience to be aware of correct speeds and feeds, consult with tooling Manufacturer to maximize efficiencies. Today’s tooling is very engineered and it definitely pays to know the dimensions and correct speeds and feeds to employ. Using the correct speeds/feeds will mean your parts are cutting faster, rrt’s going to mean that your tooling can last longer!.