Typically, may want to make 4 cavities, may produce 4 exactly identical plastics parts when all things are finally finished. Thing are going well, you have run submitting to directories 6 different shaped electrodes through the process, there is just one more. Only another 16 hours and you will be done and onto another project.

So, the mold maker gets the steel a concern . shapes, and puts these questions holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, be aware the little ugly lines on the part, or little fins of plastic sticking out, like you might see on the cheap Chinese toy.

Use in the correct cutting tools can increase end production CNC Machining . If you do never the knowledge or experience to learn the correct speeds and feeds, consult with the tooling Manufacturer to maximize efficiencies. Today’s tooling is tremendously engineered locations definitely pays to have the measurements and correct speeds and feeds to employ. Using the correct speeds/feeds will mean your parts are cutting faster, it will mean your tooling will last longer!.

Note: The A-axis will be the rotational axis. Why does it come with called that may? I don’t know. Is actually important to also sometimes called the B-axis. I have even heard it known as W-axis. A-axis is the rotational axis around the X-axis. B-axis is the rotational axis around the Y-axis.

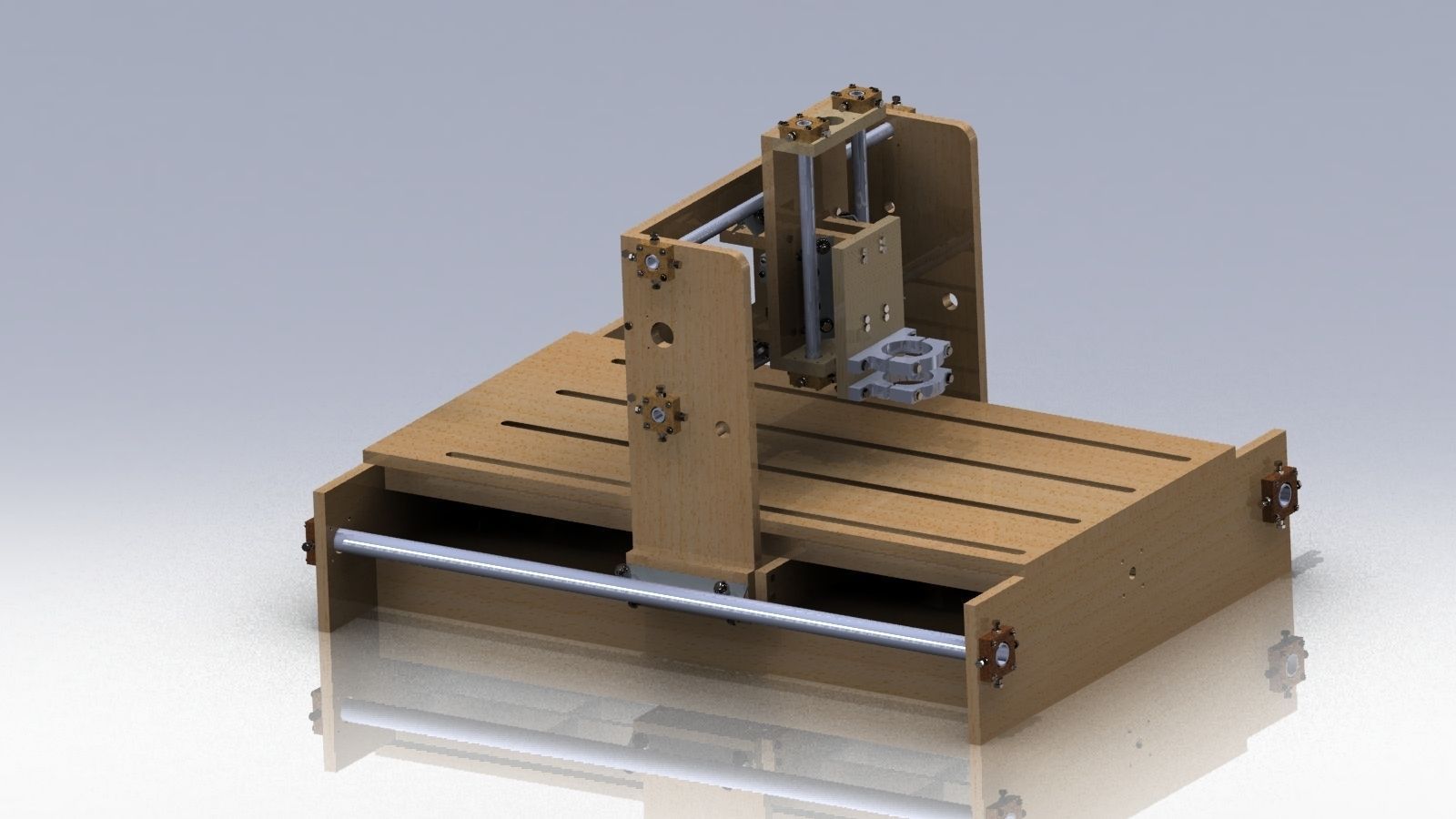

Gecko Drivers seem to the cost effective on business right now with great help. I have used Gecko drivers two of my creations so that they work helpful. Next, is a processor to perform the computing your job. A power source to power the controller. Finally the external cabling that heads to be able to the motors at each axis upon your machine.

cnc machining center

Raw Material – Group orders together as up to possible. Never order cut lengths as opposed to full program plans. Full lengths of material are always cheaper then cut sections. If small pieces are absolutely necessary ask your vendor to quote you “Randoms” Of the the pieces that remain over from a previous cut order and so usually bought at a substantial discount.

After an individual carefully considered your setup and selected the proper tooling, will be important place it by and large. Start by utilizing the mid involving the speeds/feeds provided using the tooling production. Then adjust your speed/feed to find optimum cutting conditions for use in your job. Keep close and careful record of your adjustments. Record how long the tooling lasts per speed/feed pengaturan. This information is vital to good tool life operations. By optimizing the cutting process, you will see longer tool life and lower overall tooling costs.

Through 3D printing, equipment will sleep the night very small layers of cloth down as per to the design. Sometimes the detail level can be a fraction of a real millimeter. Think of this as city being constructed from 3D print out. Small buildings, stop signs, cars, and other landmarks are usually made.25 millimeters at a time, all while retiring material for the ball which encompasses metropolis. The end product will result in a ball by using a miniature city inside pc. This is very possible through 3D printing, other forms of manufacturing just can’t do a.